Car dismantler, dream job of the future

Business and education join forces

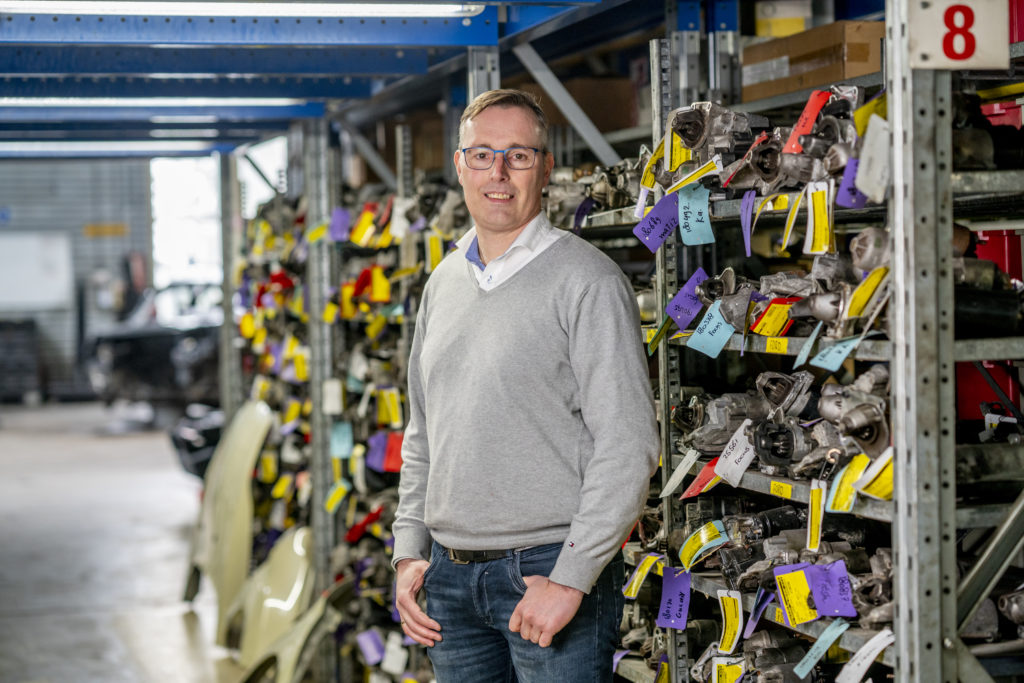

As cars become increasingly complex, the job of car dismantler is also becoming more interesting. Albert de Boer, Director of ReclyCar in Stadskanaal, is well aware that the business community and educators will need to join forces if the car-dismantling sector is to maintain a supply of well-trained employees in future. He is a staunch proponent of diligent and future-proof training.

Despite there not being a specific training for car dismantlers, it is a trade that really matters. Of all the people employed in the automotive sector, about 10 per cent of them work in the car-recycling sector. “To ready ourselves for the large number of electric cars that will have to be recycled in future, today’s employees will have to be trained and regularly retrained,” says Albert de Boer. “To underscore the continuity of your company, you have to continuously invest in your young people. They are, after all, tomorrow’s employees.”

Recruiting tomorrow’s employees

For many years now, this Stadskanaal-based entrepreneur has been able to successfully bind future employees to ReclyCar. “In our experience, technology students often think that following an internship at a garage will allow them to tinker on new cars,” explains De Boer. “But a garage has a responsibility towards its customers, so in fact trainees enjoy less freedom to tinker there than they would at a car-dismantling company. We think these students will learn more with their hands than they will from books. With us, they have the freedom to put the theory they learn at school into practice.”

How does a gearbox work, for example, and how do the gearwheels in a gearbox interact one another? In a car-dismantling company, students can see exactly how a car is put together. “And not only does this teach them a lot, it also fires their enthusiasm for this wonderful profession while they are still young,” continues De Boer. “It’s already difficult to find staff and this is a situation that’s expected to become even worse during the coming years. By forging a bond with work-experience students, you’ll win them over and make them feel at home while they are still young. In our immediate environment we see that companies that don’t offer work-experience places to students find it more difficult to recruit the right people.”

Advantages

De Boer is convinced that binding with youngsters offers another important advantage in that it removes a negative preconception. “Once upon a time, breaker’s yards had a poor reputation, which is largely still the case among the parents of these students. If you can show those same parents how good and well organised car-dismantling companies are nowadays, you can neutralise that preconception.” The company appeals to pupils as young as possible, those still at primary school. “We give them guided tours and ask them several questions that they can answer in groups. Injecting a competitive element into it all and ensuring that there is a winner at the end makes them pay even more attention.”

Another advantage of working at a dismantling company, as opposed to a garage, is that at five o’clock you can simply stop and pick up where you left off the following day, continues De Boer. “There is more time pressure associated with working for a garage, because customers want to collect their cars at the end of the day.”

We believe that these students learn more with their hands than from books. With us, they can put into practice the theory they learned at school

Albert de Boer

Managing Director Reclycar

Increasing complexity

Training and courses

Collaboration with regional training centres

Train locally

De Boer is a huge proponent of local training. “If all companies were to have their employees trained nearby it would save travel time, thus removing the barrier to participation for many employees and employers. Moreover, it would also be more sustainable.”

Despite the intensive role he already plays in stimulating young talent, De Boer still identifies clear opportunities for further development. This year, for example, he and his company intend to explore how their collaboration with ROC Noorderpoort can be taken a step further. “We are also investigating how we can connect with other ROCs, so that, as a sector, it will be possible to develop courses that are even more in line with the real world. In this way we can collectively ensure that we are ready for whatever the future throws at us!”

We are also investigating how we can connect with other ROCs, so that, as a sector, it will be possible to develop courses that are even more in line with the real world. In this way we can collectively ensure that we are ready for whatever the future throws at us!

Albert de Boer

Managing Director Reclycar

More about ReclyCar

Reclycar has been located in Stadskanaal for over 25 years and the car-dismantling company has become a household name in the region. Ten employees work on the company’s two-hectare site, processing between 800 and 1,000 vehicles every year. The warehouse contains about 50,000 parts, which are offered to international customers via a six-language webshop. During the 2020/2021 school year, a professional jury put together by ROC Noorderpoort voted ReclyCar the first and best company in professional vocational training.

Sustainable Development Goals

For the fourth year, ARN is benchmarking itself against the Sustainable Development Goals (SDGs) with the motto ‘lean and green’ in mind. The coloured SDGs shown on the right apply specifically to the content of this page.